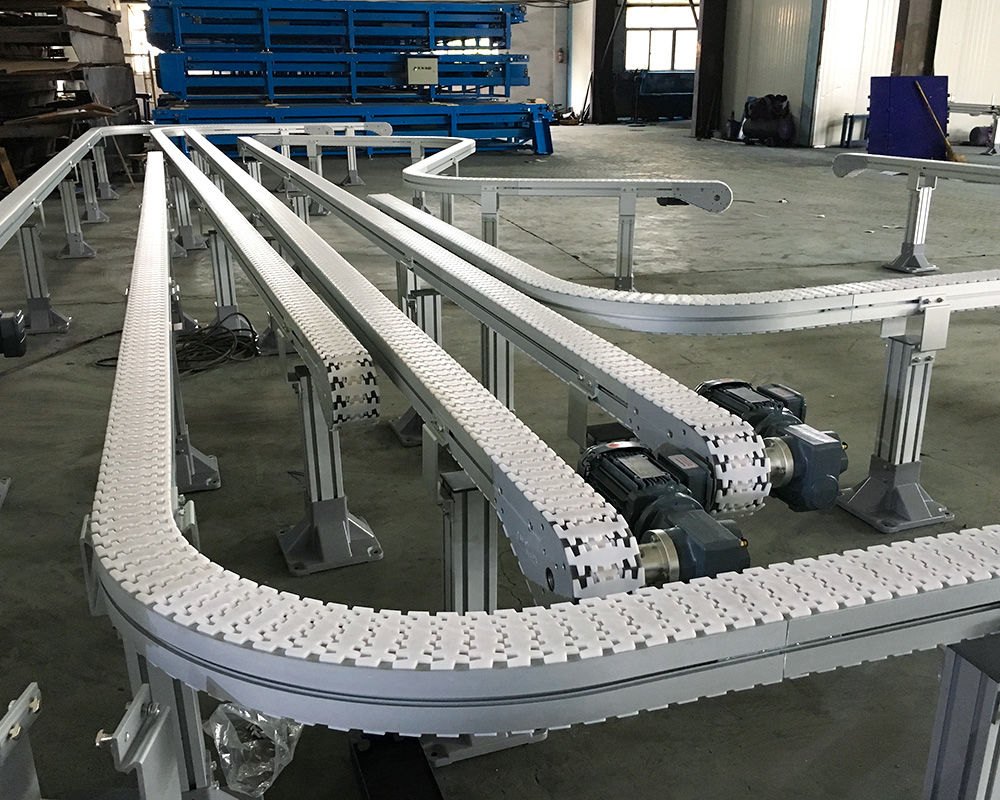

Plastic Chain Conveyor

A plastic chain conveyor is a type of conveyor system that utilizes a chain made from plastic links, allowing for flexible movement of products around bends, inclines, and declines, often used in applications where delicate items need to be transported without scratches or damage, while also being resistant to chemicals and contamination due to its plastic construction; this modular design enables customization to fit specific product sizes and application needs with minimal maintenance requirements.

Key points about plastic chain conveyors:

-

Flexible Chain:

The primary component is a chain made from interlocking plastic links, providing flexibility to navigate tight corners and different levels.

-

Gentle Handling:

The plastic material is designed to prevent scratches or damage to delicate products.

-

Customizable:

Modular design allows for easy adjustments to conveyor width and configuration to fit various product sizes.

-

Diverse Applications:

Suitable for applications involving chemicals, cold storage, high heat environments, and more due to the choice of plastic materials.

-

Space-Saving:

Tight bends and vertical transitions enable efficient use of floor space.

-

Low Maintenance:

Plastic chains generally require less lubrication and maintenance compared to metal chains.

Common uses of plastic chain conveyors:

- Packaging lines: Moving delicate products like bottles, boxes, or pouches without damaging them.

- Food processing: Transporting food items through cleaning and sanitation stages due to the easy-to-clean plastic surface

- Electronics assembly: Conveying sensitive electronic components

- Pharmaceutical manufacturing: Handling delicate pills or vials in controlled environments