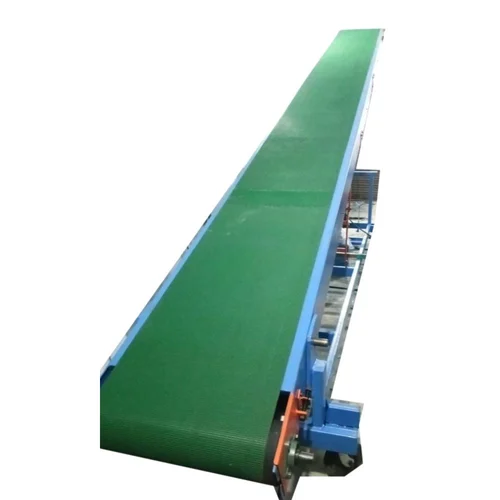

Belt Conveyors

RP Automation is a leading manufacturer of innovative conveyor systems, material handling solutions and Loading unloading conveyers. Our extensive range of products includes belt conveyors, chain conveyors, roller conveyors, slat conveyors, PVC belt conveyors, truck pallets, scissor lifts, and more.

A belt conveyor is a mechanical system that moves materials, goods, or people from one place to another using a flexible belt that runs between rollers. Belt conveyors are versatile and can transport materials horizontally or on an incline.

Here are some key features of belt conveyors:

- Components: The main components of a belt conveyor are the belt, idlers, pulleys, and drive.

- Belt: The belt is made of one or more layers of material, such as rubber, woven cloth, steel, polyester, nylon, cotton, or aramid.

- Pulleys: Two motorized pulleys support the belt and control its tension.

- Idlers: Idlers support the belt's carrying and return strands.

- Drive: The drive imparts power to the pulleys to move the belt and its load.

- Transportation: Belt conveyors can transport bulk materials like coal and crushed limestone in cement plants.

- Sorting: Belt conveyors can be used to separate good and bad products alongside a sensor.

- Maintenance: Proper loading conditions and regular maintenance are important to prevent belt wear and failures.

Belt conveyors are classified by their design and application as general purpose or special purpose, and by their profile path as horizontal or inclined.